Cross-Dock Clarity: How Last-Mile Carriers Can Track Every Product, Fast

Cross-dock days are busy. Trucks arrive. Pallets roll. Goods move in minutes, not hours. There is no time for long warehouse intake. Yet retailers still ask the same question: “Where is my product right now?”

This guide shows a simple, clear way for last-mile carriers to track every item in a cross-dock flow. We will use plain words, short steps, and a story that follows a clean plan. You can give this to your teams today.

Why Cross-Dock Needs Real-Time Inventory Tracking ?

Many Vendors, Many Labels, One Truth

Cross-dock means speed. But it also means mix.

You receive products from many vendors for many retailers for many customers—all at the same time. Boxes arrive with different barcodes. Some use serial numbers in different spots on the label. Some use plain text in a corner. Some have both.

You need to move fast. You must transfer from inbound truck to outbound route in minutes. There is no time to do a full warehouse “receiving” like a slow DC (distribution center). Still, you must prove where each item is:

- “Received at warehouse” (really, at cross-dock)

- “Assigned to a route”

- “Out for delivery”

- “Back to warehouse”

- “Return to vendor haul”

Retailers require this. Customers expect this. CSRs (your support team) depend on this. And TMS needs it to plan routes.

When labels differ and time is short, mistakes grow. Items get lost. Calls go up. Crews wait. Money slips away.

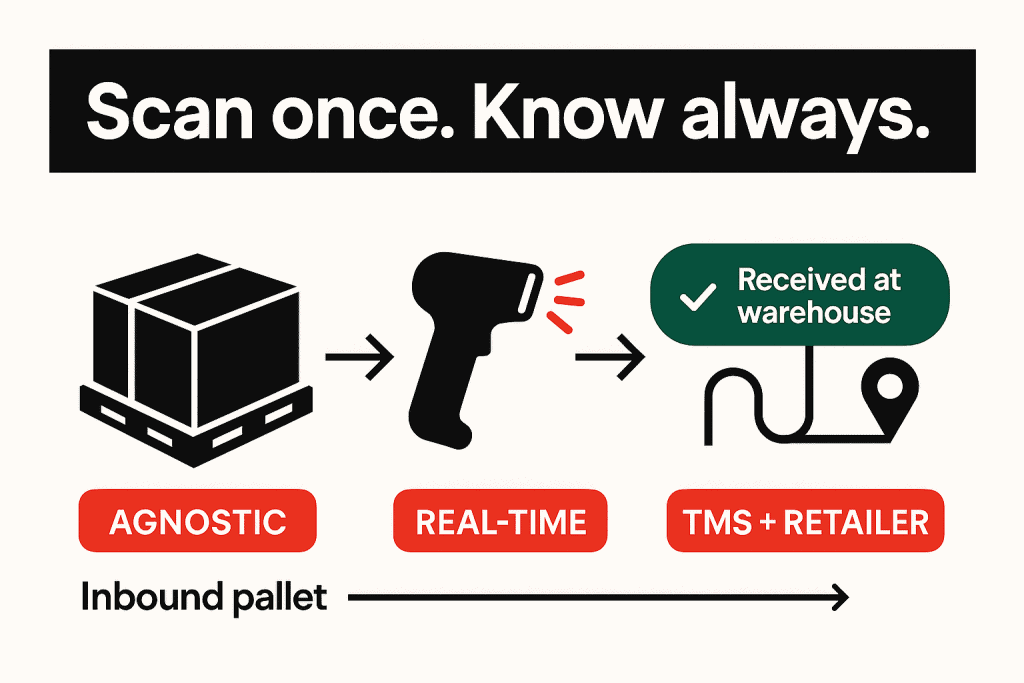

The Agnostic, Scan-First Approach

The answer is an agnostic inventory management system.

“Agnostic” here means the system does not care which vendor or retailer made the label. It can read many kinds of serial numbers and barcodes. It can map fields from any file. It can report to any TMS or retailer system in real time.

Think of it as a “universal translator” for labels.

- Different vendors? No problem.

- Different barcode types? No problem.

- Many retailers? No problem.

This system holds one simple rule: the serial number is the identity of the item. If we can scan it, we can track it—from the door, to the route, to the home, and back if needed.

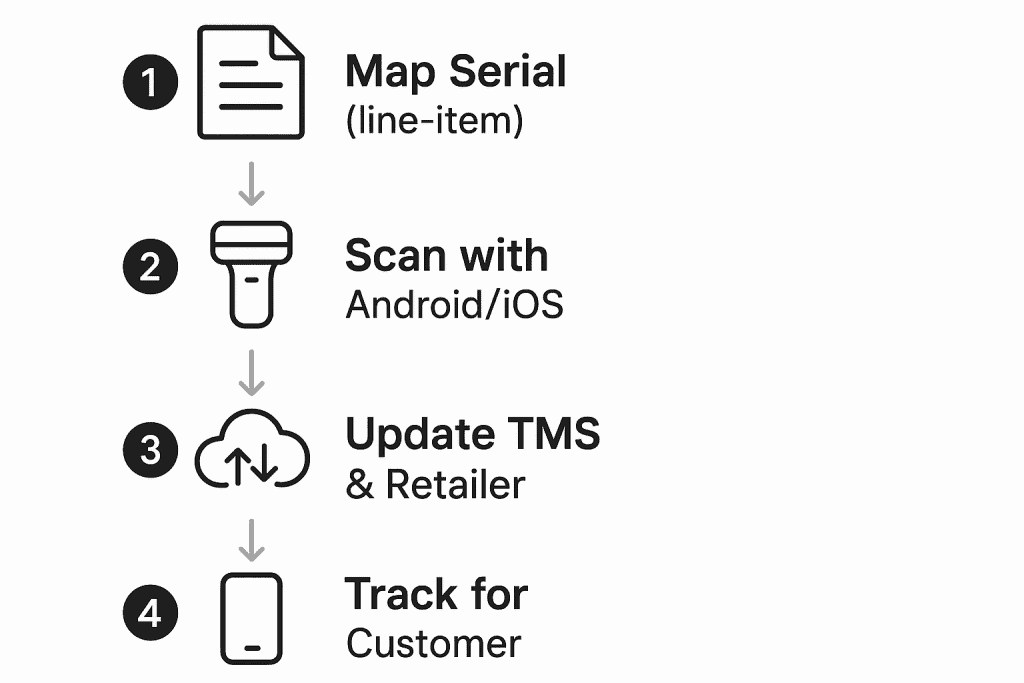

Map → Scan → Update (MSU)

Map the Serial at Line-Item Level

When partners send order files, map the correct serial or barcode field at line-item level.

- If a file has service lines (install, haul-away, etc.), do not map those as items. Service lines are not inventory.

- Save every serial number on the line item in your database. This is your “single source of truth.”

Result: your system knows where to look for the serial before the truck shows up.

Scan on Android/iOS (No Typing)

Any barcode scanner that connects to your system on Android or iOS can do the job. In our case, we built an Android app for 3D barcode scanners. It talks to the database in real time. When a worker scans, the app instantly knows the item, the order, the retailer, and the next step.

Result: fast cross-dock intake with no typing and no waiting.

Push Status to TMS & Retailers in Real Time

As soon as a barcode is scanned, the app sends a status to your system, and your system pushes the status to:

- TMS (so dispatch knows what is ready and where it is)

- Retailer system (so partners see proof with timestamps)

- Customer tracking site (so the end customer can see movement)

Statuses are simple and clear:

- Received at warehouse (cross-dock)

- Assigned to route

- Out for delivery

- Back to warehouse

- Return to vendor haul (if it comes back)

Result: everyone has the same truth, at the same time.

What You Lose Without This

Without this simple flow, you face:

- Lost time during morning picks (CSRs and crew hunt for items).

- Slow staging and loading (routes leave late).

- Manual serial reports that eat hours and still miss items.

- Blind spots for CSRs (“I don’t know where your product is”).

- Customer confusion (no real-time tracking).

Speed is the life of cross-dock. If you slip, you pay. If you track, you win.

What You Gain With It

With an agnostic, scan-first system, you get:

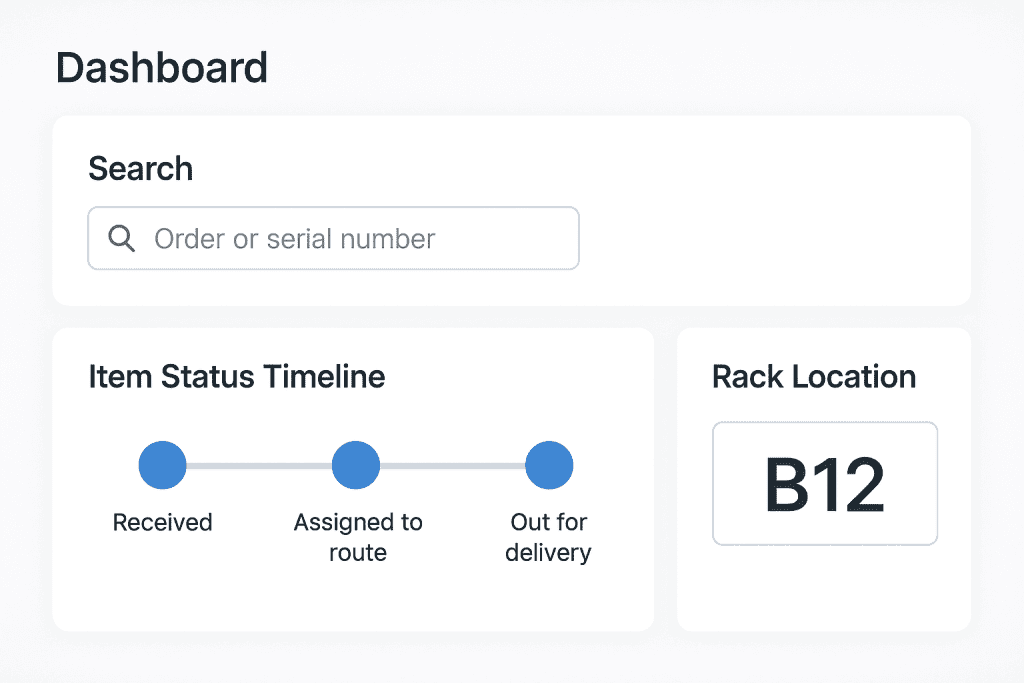

- Fast picks: the system tells crews where each item is right now.

- Quick staging & loading: items move to the right route without guesswork.

- Zero double entry: you do not retype serials. You just scan.

- CSR clarity: one screen shows the item, the status, the route, the proof.

- Customer trust: the tracking page shows live status with real timestamps.

- Retailer confidence: partners see “Received,” “Assigned,” “Out for delivery,” or “Return to vendor” without emails or calls.

- TMS sync: planning is better because the truth is fresh.

A Morning That Used to Be Hard

Before the system, a cross-dock morning felt like a race with a blindfold.

Inbound trucks would arrive. Pallets rolled off. Labels looked different. Some boxes had tiny serials. Some had two barcodes. Some had none on the visible side. People walked the floor looking for “that one fridge for Mrs. Lee.” Time passed. Dispatch waited. CSRs took calls. Routes left late.

After the system, the scene changed:

- A worker scans the item at the dock.

- The app shows “Received at warehouse,” with order and route info.

- The system pings the TMS and the retailer.

- A rack location suggests itself.

- When it is time to load, the picker scans again. The app confirms “Assigned to route.”

- Customer tracking updates.

- If the item returns, one more scan marks “Back to warehouse” or “Return to vendor haul.”

No hunt. Just flow.

Keep It Simple, Keep It Open

To make the system agnostic and fast, follow a few rules:

- Open inputs

- Accept many file types (CSV, JSON, EDI).

- Map the serial/barcode field at line-item level.

- Save that serial in your database as the item’s key.

- Open scanners

- Support Android and iOS.

- Support popular 2D/3D barcode scanners.

- Keep the app simple: scan → confirm → done.

- Work offline for short periods; sync when online.

- Open outputs

- Push status to TMS instantly (webhook or API).

- Push status to retailer instantly (their spec).

- Update the customer tracking page at the same time.

- Log every event with user, time, and device.

- Open screens

- Give CSRs one screen to search by order, serial, or customer.

- Let warehouse leads see “received,” “staged,” and “missing” at a glance.

- Give dispatch a “ready vs. not ready” view by route.

Tiny Habits That Make a Big Difference

- Scan on arrival. Do not wait for count sheets.

- Scan on move. Each move updates the system and the route.

- Scan on load. Confirm the truck, the stop, the order.

- Scan on return. Mark items for vendor haul the second they come back.

- Use short labels. Train teams to look for the serial spot first.

- Make it visible. Big screens show “what is missing” so teams can fix it fast.

Why Retailers Demand It (and Why You’ll Like It)

Retailers require serial tracking because it protects the whole chain. If there is a damage claim or a warranty question, you have serial + status + time for every step. This ends “he said, she said.” It saves calls. It speeds pay. It builds trust.

You will like it, too, because it gives you:

- Fewer pick errors

- Faster loads

- Lower morning stress

- Cleaner invoices

- Happier customers

A Simple Example Flow (Minute by Minute)

- 06:55 — Inbound truck arrives.

- 07:00 — Worker scans serial. Status: Received at warehouse (pushed to TMS + retailer + tracking).

- 07:12 — Item staged to Route 12; scan sets Status: Assigned to route.

- 07:40 — Truck loads; final scan confirms load.

- 10:15 — Driver leaves; Status: Out for delivery.

- 12:30 — Delivered. If a return is needed later, a scan marks Back to warehouse or Return to vendor haul.

Every scan is a proof point. No manual report. No delay.

Common Questions (Quick Answers)

Q: What if a label is damaged?

A: Use the order lookup or manual serial entry once. Print a small replacement label on the spot.

Q: Can we use our own scanners?

A: Yes. Any Android/iOS device that can scan to the app will work. We built an Android app for 3D scanners, but the system accepts many devices.

Q: Will this slow the dock?

A: No. A scan takes seconds and replaces minutes of searching later.

Q: What if a vendor changes label format?

A: Update the mapping for that vendor. The system stays agnostic.

One route. One week. See the change.

Start Small. Win Fast.

You do not need a big rollout to see value. Try this:

- Pick one inbound lane, one retailer, one route.

- Map the serial field.

- Scan every item.

- Push statuses to TMS, retailer, and tracking.

- Watch picks get faster tomorrow morning.

If your team wants our Serial Mapping Starter Kit (templates, field guides, and sample screens), ask for it.

Next step: Let’s set up your pilot. We’ll help you map your first file, test scans, and push live statuses in under a week.

Final Word

Cross-dock is all about speed. With an agnostic, scan-first system, speed does not kill control—it creates it. Map the serial at the line item. Scan with any device. Update every system at once. Then watch your mornings calm down, your routes leave on time, and your partners smile when they see the truth on their screens.

Because in last-mile, the product your customer wants is not just the couch or the fridge. The real product is trust—and trust starts with a scan.